Table of Content

- How do you compress springs to lower a car?

- Loosen the Lug Nuts

- How to Repaint a Car Bumper

- Q: How do I use a strut spring compressor?

- How to Lower a Car Suspension: Using a Lowering Kit With Lowering Springs

- Can you cut Springs while on the car?

- Why you shouldn’t cut your springs?

- Take the Car’s Front Strut Assembly Off

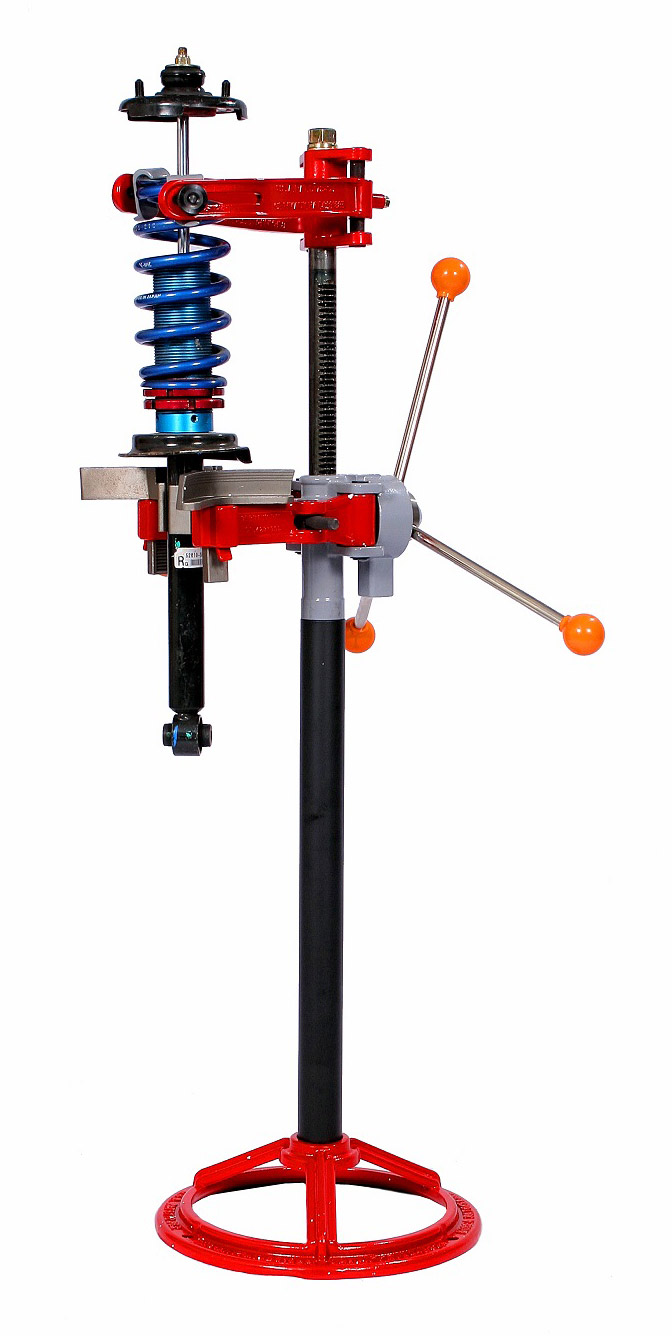

The vehicle should be raised and supported on jack stands prior to doing any of this work. The weight of the vehicle will act as the support on one end when decompressing the spring. One downside is that it's really heavy with a coil spring in it. Also, it doesn't come with any instructions, and it does not work on all vehicle models. In addition, it can be very difficult to remove old warped springs with this tool.

Lowering a car suspension is perhaps one of the most common modifications anyone can make on a vehicle. A lowered suspension typically helps increase the aesthetic of a car. That completes the No Spring Compressor Method, which in my opinion is the safest way to handle diassembly and reassembly of shock assemblies at home.

How do you compress springs to lower a car?

The other three nuts that surround the center nut hold the shock assembly to the body of the vehicle. When the spring needs to be be compressed again, the floor jack will be used to push up on the LCA and in effect the spring will be compressed into place. The center upper shock nut will then be tightened to complete the installation.

Once you have reinstalled the strut onto the car, you can place the wheel back and tighten the lug nuts. You can then move to conduct the same procedure on the other side’s strut assembly. This process requires you to pay close attention to how the lowering springs are placed on the strut perch. If they are placed incorrectly, the holes are unlikely to line up when installing these lowering springs onto the strut assembly. The plates are pitched to match the slope in the helix of the spring.

Loosen the Lug Nuts

This static energy can spell disaster if you don’t use a spring compressor to control the springs’ decompression. It handles the heaviest coil-over-shocks on light trucks and SUVs and has longer handles for extra torque. The corkscrew design makes it easy to compress, and spring tension aides in decompression. The compressor will not work on every vehicle and is intended for small cars and light-duty suspension. The pins may bend and may not retract after you're finished with the job.

Most of the kits that you can purchase at your local auto parts store are meant for light-duty vehicle springs. Any vehicle beyond that will require heavier-duty tools, so don’t attempt to use a light-duty compressor or you may get hurt. Your strut spring compressor should come with a good storage case that you can use several times without breaking. Having a safe, clean, dry place to store your compressor tool is paramount to its longevity and usefulness.

How to Repaint a Car Bumper

The safest choice overall is to have a shop handle this type of work, but if that is not an option this one works superbly. Make sure the coil spring is rotated within the shock so that the top and bottom of the coil matches the top and bottom perches as shown below. I find going with the lower bracket nuts easier to deal with.

Also, the threaded rods are strong and well-machined, so as long as you keep them clean and well lubricated this kit should last for a while. Fargo, South Dakota’s Branick Tools is one of the most recognizable names in tire and suspension tools. Its strut spring compressor set the standard for all standing compressors today. Branick recognized that these heavy machines aren’t easy to move around a shop, so it developed the Branick Portable Cart for 7600 compressors. I was happy to pay for something that was the right tool for the job, worked quickly and efficiently, and was commercially available and thus presumably vetted for safety.

The ones I own are probably 40 years old, high quality, American made, and the claws are plenty long enough to wrap around the spring and hold it. I see that some of the new ones now being sold address the slippage issue by having pins that lock the claws in place around the spring. Use the strut spring compressor to compress the spring.

Also, it may slide a little bit more than you like, and there have been some complaints that on some larger vehicles it can't grab the spring with both hooks. The OEMTOOLS MacPherson Strut Spring Compressor kit is our pick for the Best Overall Strut Spring Compressor. This is an externally-mounted kit that locks onto the coils of a spring and compresses it for easy removal. Considered "the standard in the industry," this all-steel, premium product does not require any adapters and uses heavy-duty acme thread. It features versatile mounting options and multi-position hooks. It's easy to use, and the safety pins keep everything locked in place.

Therefore, you can’t compress the spring anymore, even if you still have more to compress. This strut spring compressor from 8MILELAKE has drop forged jaws that have a minimum jaw distance of four inches and a maximum opening of 14 inches. The jaws and lead screws are heat treated for optimal performance, and the zinc-plated tool fits most Macpherson struts. The first is the ubiquitous style with a pair of threaded rods, each of which have pronged “claws” at the top and bottom. You place one of them on each side of the spring, then tighten them evenly with a wrench or a socket on the nut at the top of the rod. Because, structurally, there’s not much to them, and because if they break or slip the results can be catastrophic, these claw compressors have gotten a bad rap over the years.

Do not use the stock rubber spring seats, as the new car suspension system should come with its own set of rubber spring seats. The alignment cams should be in about the same position of where you marked them. Now, get the floor jack into position so that when it jacks up the lower control arm, it contacts the very end of the LCA.

You can put the hooks around the top to keep it from sliding. As long as you’re careful, evenly distribute the load, and grease it before use, this tool does the job. OTC Tools has been a subsidiary of Bosch Automotive Service Solutions since 2012.

No comments:

Post a Comment